Highly Efficient Bio Fuel Pellet Line Customized for You

From Bio Materials to Bio Fuel

Biomass is becoming an increasingly popular word around the world, more and more people start to talk about biomass, such as, biomass technology, biomass energy, biomass material, biomass fuel etc. Then, what on earth is the biomass? In fact, it means using biomass technology to make bio materials into bio fuel, which is called biomass energy, we can make it full use to bring values to our lives.

From bio materials to bio fuel, not only the residues storing problem is solved well, but also new and green energy has been produced for our life. The finished bio fuel pellet has high density and good combustion, burning with more heat value but no ashes produced, is a good substitution of traditional fossil fuel.

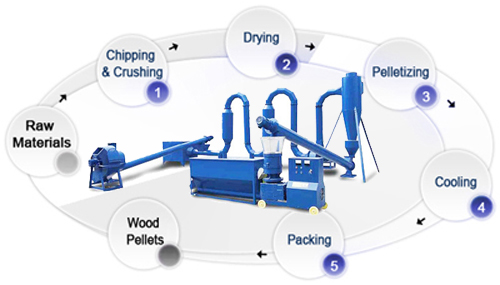

How to Make Bio Fuel?

Bio fuel pellet line is professionally designed and manufactured for producing bio fuel, consisting complete equipments including crushing, drying, pelleting, cooling, packing. In the actual bio fuel pellet production, the equipment of those machines are not fixed, it is can be customized according the requirements of users and actual situations. At the first crushing stage, hammer mill or crushing machine is equipped to crush the raw material into the small size less than 3mm. If your raw material is in large size like wood log, bamboo or branches etc, you also need to equip the chipping machine. If your raw material is in small size, like wood chips, shavings, straws, wood residues etc, the hammer mill is enough.Except of the size requirement, making bio fuel pellet also requires the moisture content of raw material, thus the next section is drying process. We have two types of drying machine with different working principles, respectively are air flow type and drum type, both of them can decrease the moisture content to the range of 12%-15% with high efficiency. We can equip the most proper drying machine type according to your raw material condition and your requirements.

When the raw materials are prepared well, it is time to the key pelleting processing in bio fuel pellet line. We equip the flat die pellet machine in this section. Flat die pellet machine has different production capacity ranging from 50kg/h to 400kg/h, can produce various kinds of specifications of bio fuel pellet, such as, diameter with 4mm, 6mm, 8mm, 10mm which is decided by the compression ratio of the pelleting die. The type of pellet machine can be decided by the requirements and actual situation of users.

At the last processing, the cooling machine and packing machine are optional which is decided by the applications of finished bio fuel pellets. If you make pellet for home use, these two machines are not so necessary, you can put the pellets in a cooling place to cool them naturally; if you make bio fuel pellets in factory used for selling, these two machine are very necessary, thus the production efficiency can be improved a lot and the time cost will be reduced.

Why Choosing Bio Fuel Pellet Line?

- All the equipments in the bio fuel pellet line are made from the international high quality material, the life time has been prolonged.

- With complete systems equipped, the production efficiency of bio fuel pellet line is improved a lot.

- The bio fuel pellet line is designed with compact and reasonability, covering a small area, costing less investment, is a good project for investment.

- Through the complete production, the finished bio fuel pellet has high quality with high density, brighter surface, better combustion.

- The whole bio fuel pellet line can be customized uniquely according to the requirements and actual situation of users.

Categories