GEMCO Portable Small Pellet Production Line for Sale

GEMCO portable small pellet production line is designed to manufacture high-density biomass pellets with such raw materials as sawdust, straw, rice husk and tree bark, etc. Biomass pellet is a kind of high efficient clean renewable energy with the advantages of saving energy and reducing carbon emissions. It is widely used in house-warming and power generation in an environmental friendly way instead of the non-renewable energy resources such as coal, oil, gas, etc. That not only saves energy but also reduces the carbon emission, so it is a kind of clean and renewable energy source with high efficiency. Biomass pellets are also easily stored and transported.GMC-ZCP420D portable small pellet production line

Main Technical Parameters:- Capacity: 400-600 kg/h

- Total Power: 56.81kw

- Pellet Size: 6、8、10、12mm in diameter

- Boundary Dimension: 3500*1960*3500mm

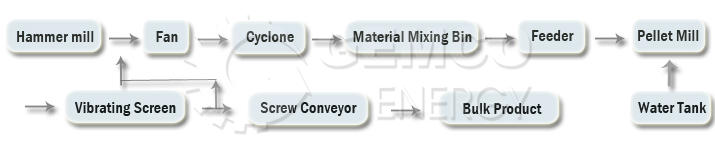

Operational Principles of Complete Biomass Pelletizing Unit

The biomass materials like waste wood or straw after being broken into powdery particle by the hammer mill will be sucked into the storage bin through cyclone dust collector and then conveyed into pellet mill by adjustable-speed feeder. The finished pellets will be cooled in cooling conveyor through a vibrating screen. Cooling the pellets to ambient temperature makes it easier to transport and storage.Technological process

Key Equipment: ZLSP420B Pellet Mill Unit

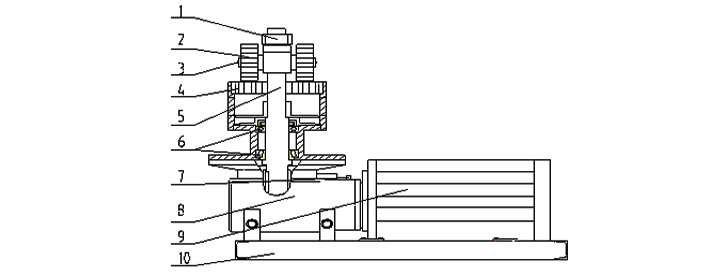

GMC-ZLMG420Bpellet mill structure

1、Adjusting nut 2、roller 3、oil filling hole 4、die 5、main shaft

6、bearing 7、oil filling hole of speed reducer 8、speed reducer 9、motor 10、base frame

The ZLSP420B pellet mill consists of base, motor, reducer and pellet machine, etc. the biomass material is made into compact pellets by the force of die and rollers. It's belong to R-type pellet mill.1、Adjusting nut 2、roller 3、oil filling hole 4、die 5、main shaft

6、bearing 7、oil filling hole of speed reducer 8、speed reducer 9、motor 10、base frame

Technical Parameter

| No. | Item | Unit | Number | Remarks |

| 1 | Production capacity | kg/h | 400-600 | |

| 2 | Power | kW | 37 | |

| 3 | Weight | kg | 950 | |

| 4 | Outer dimension | mm | 1630*620*1450 | length*width*height |

Anyang GEMCO Energy Machinery Co., Ltd, which boasts the earliest enterprise engaging in manufacturing biomass processing equipment (including biomass pellet mills and complete plants) and renewable energy machines, possesses certificates of ISO9001 and CE. As one of the key renewable machinery manufacturers, GEMCO also enjoys the national encouragement policies. Remarkably, our products have been serving clients overseas across more than 100 countries and regions. Having state of the art manufacturing equipment, we dedicate to R&D, manufacturing, installing, and debugging biomass energy machines as a whole. Our products have enjoyed a good reputation at home and abroad.

Categories