small feed mill cooler

LQS series small feed mill cooler is a special equipment for cooling and sieving the hot feed pellet from feed pellet machine, called small cooling machine as well, suitable for cooling all kinds of feed pellet, such as, livestock, poultry and aqua animal feed pellet etc.

Main Technical Parameter

| Model | Capacity(kg/h) | Power(Kw) | Mainframe weight(kg) | Dimension (mm) |

|---|---|---|---|---|

| LQSF50 | 250~350 | 0.75+2.2 | 220 |

1700*880*1000 1050*1000*730 |

| LQSF70 | 300~500 | 0.75+2.2*2 | 280 |

1900*880*1000 1100*1000*730 |

Character for Small Feed Mill Cooler

- Simple structure, easy operation and maintenance.

- Small size, covering a small area.

- Low consumption, but high sieving rate.

- Sieving hole is not easy to be blocked, ensuring longer life time.

How does the Small Cooling Machine Work?

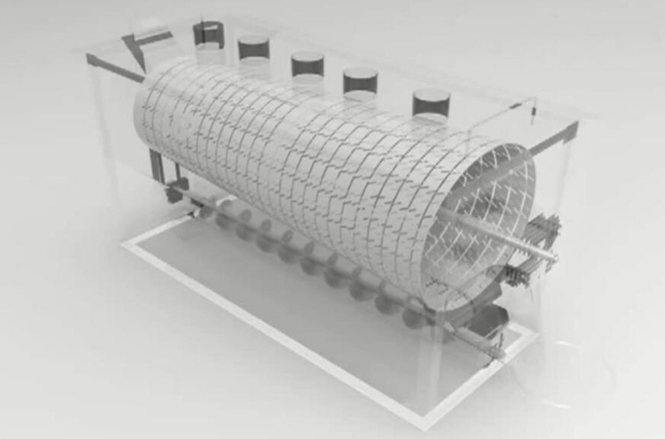

The small cooling machine is mainly composed of shell frame and drum, with the drum having a certain angle with the ground level, integrating functions of cooling and sorting.

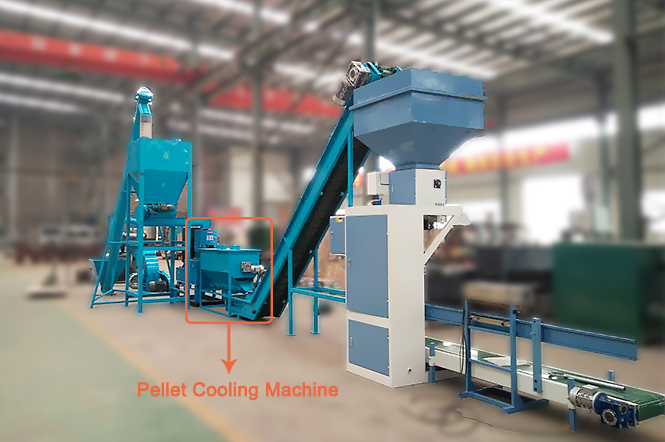

Used in Feed Pellet Plant

Feed pellet plant is series of equipments connected together to realize continuous feed production. Although cooling processing is the last process, it is very important for quality of final feed pellet.Usually, small feed mill cooler is connected to draught fan through air inducting pipeline, so that the dust will enter into the dust collector while the cooled feed pellet is placing into the packing bags through the discharging hole of small cooling machine. We can configure different small cooling machine for different small feed plant with different requirements.

Vital Role in Feed Pellet Production

It is widely known that feed pellet is formed in high temperature and pressing, thus the finished fresh feed pellet has a high temperature. Packing the hot feed pellet in to bags will result the steam which makes the feed pellet easy to go mouldy, harmful to animal health.

(Feed pellet without cooling: coarse surface, high softness.)

VS

(Cooled feed pellet: high hardness, brighter and smooth surface.)

Decreasing feed pellet temperature from 70~85℃ to close indoor temperature, small feed mill cooler has high efficiency ensuring the continuous feed pellet production. Besides, small cooling machine can cool the feed pellet meanwhile sorting them, further improving the feed pellet quality, very suitable for your small feed pellet production.

Categories